Believe it or not, this post will not be about E. Reeve Musk. Or about Tesla sales volumes, share price, autonomous driving, or even Cybertruck. I just want to show how hard it is to reduce product costs in automotive, even for an innovative (I just can’t bring myself to use the D-word) new(ish) arrival on the OEM scene.

In this post I will shamelessly steal from Troy Teslike [ sic ], whom I consider to be far and away the best independent analyst on the TSLA beat. Please follow him and, if you can, support his Patreon. He is a Tesla fan, yes, but his work is scrupulously objective and fact-based, with his sources and methods always clearly and completely identified.

Recently TT posted on Tesla’s COGS position (Cost of Goods Sold), and from that work (with his permission) I am going to steal not one, but two brilliant charts.

We are all aware that Tesla’s Technoking has a deep interest in production technology (see his refrain, “The factory is the product”), and as such he has launched various experiments aimed at reducing the cost of car production. We can cite just as two examples his attempts to dramatically increase factory automation levels, and of course the Cybertruck’s avoidance of millions of dollars in paint shop investment, thanks to its unpainted stainless steel exterior. Not to mention myriads of incremental improvements made every day at every Tesla plant.

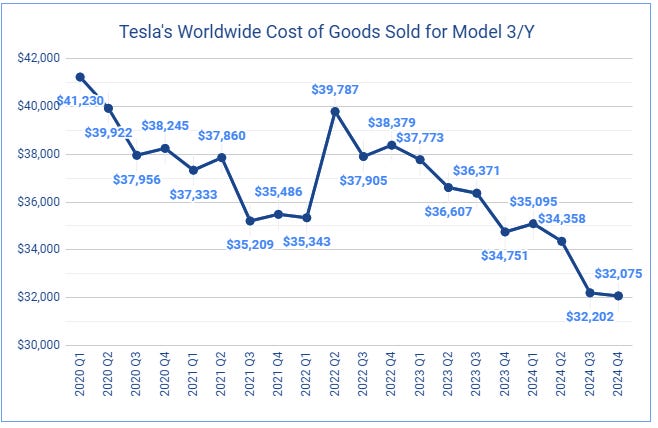

This leads us to the first chart from Troy, showing the blended COGS for all Model 3 and Model Y vehicles Tesla sells worldwide. As he writes, “At first glance, it appears that costs have dropped significantly.” (About 22%.) Perhaps indeed Tesla has found a way to slash vehicle costs?

Ah, well, not so fast. As Troy continues, “In reality, this isn’t the case. Tesla is simply selling more cars in China, which are mostly Standard-Range RWD models. This shift in sales mix is what lowers the overall COGS per vehicle over time.”

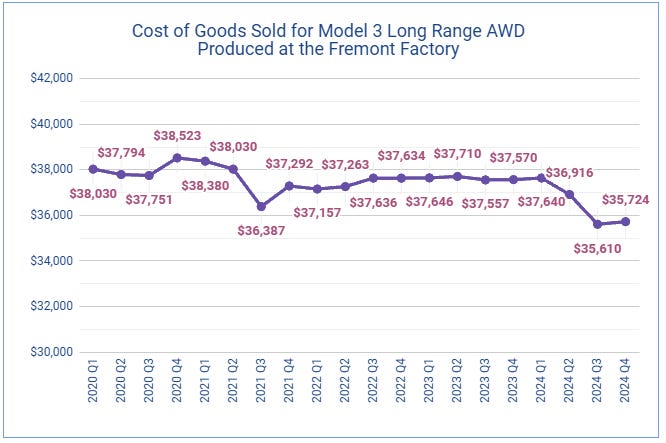

This leads us to his second chart, which tracks COGS for just one model, the Model 3 Long Range AWD, as made in Fremont. Here the effects of mix are eliminated:

(The likely cause of the 2024 drop is reduction in battery costs.) But the broader point is that over the course of about five years the total cost reduction is now only about 6%1.

It would seem that Moore’s Law does not apply in cars, even cars that are extremely software- and silicon-intensive.